Home / Engineering

Design & Engineering

Farnikan provides all equipment designs with in-house engineering and extensive experience in design and analysis. Our team of process and mechanical engineers have years of combined experience in different industry sectors, and passionately pursues engineered solutions with unique insight and innovation.

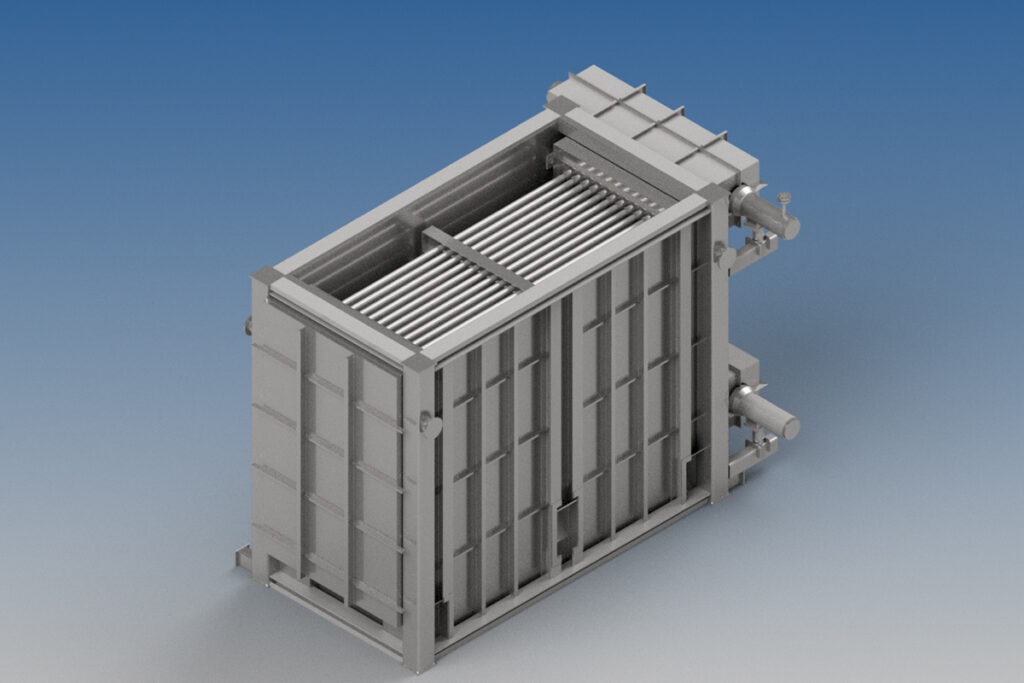

By using general purpose as well as international code based softwares, FEA and also hand calculations in accordance with all of the pressure vessel codes, Farnikan is able to design under pressure equipment such as Pressure Vessels, Heat Exchangers, Filters, Heaters, Towers & Columns and etc.

- Thermal Rating and Design

- Mechanical Design

- Finite Element Analysis (FEA)

- Computational Fluid Dynamics (CFD)

- 3D Modeling

- Engineering Drafting

We use the most well-known and internationally recognized design softwares in order to obtain the optimum thermal and mechanical characteristics of equipment. We have complete solution for our products design, analysis and evaluation.

We can design the equipment for the most extreme cases and get accurate results profitably.

Some of softwares:

HTRI, BJAC, PVelite, Compress, NozzlePro, Caesar II, Ansys.

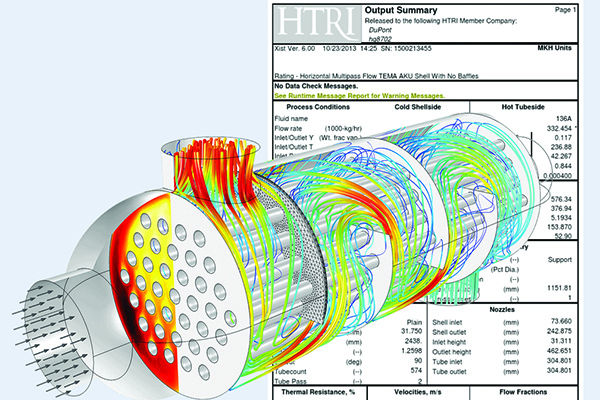

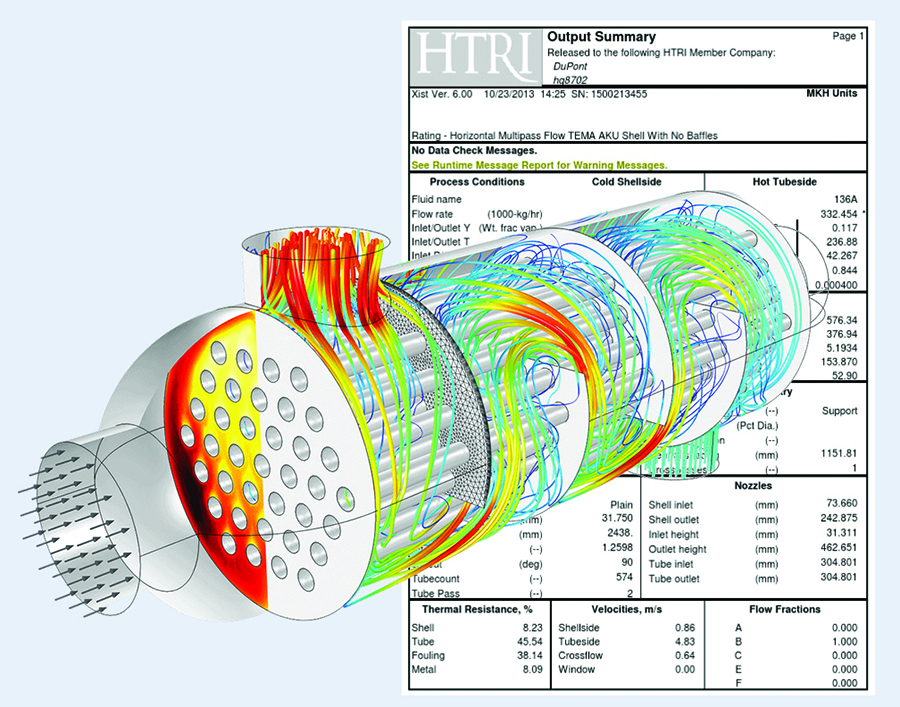

THERMAL DESIGN

We use international thermal design and rating softwares for thermal sizing or performance verification of heat transfer equipment. Thermal sizing of a heat transfer equipment is a multi-variable design challenge which presents multiple solutions for a single design case.

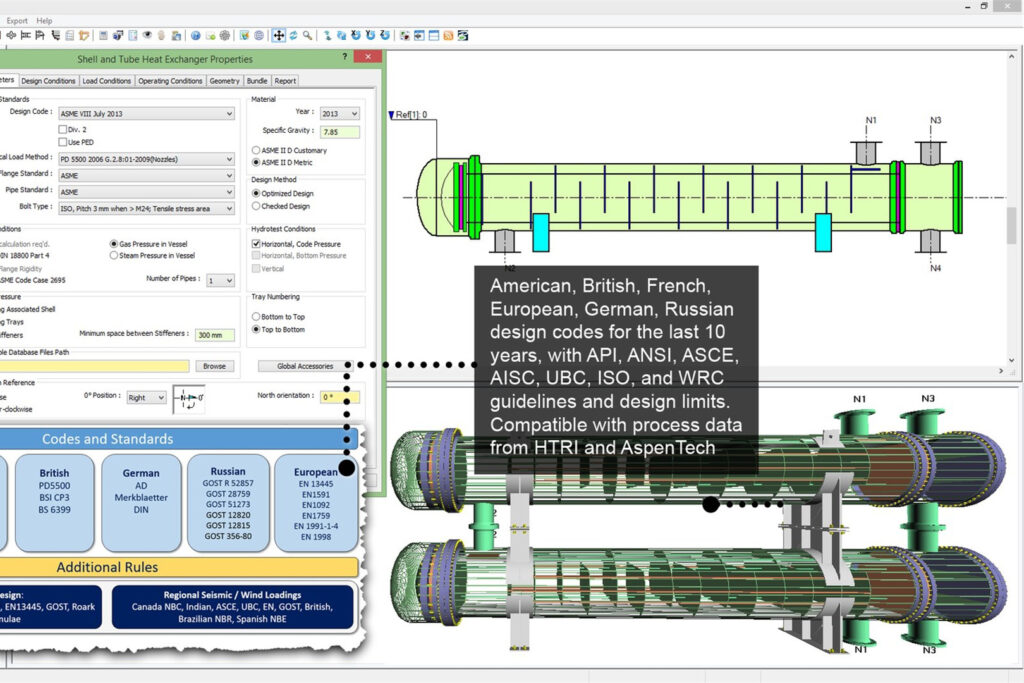

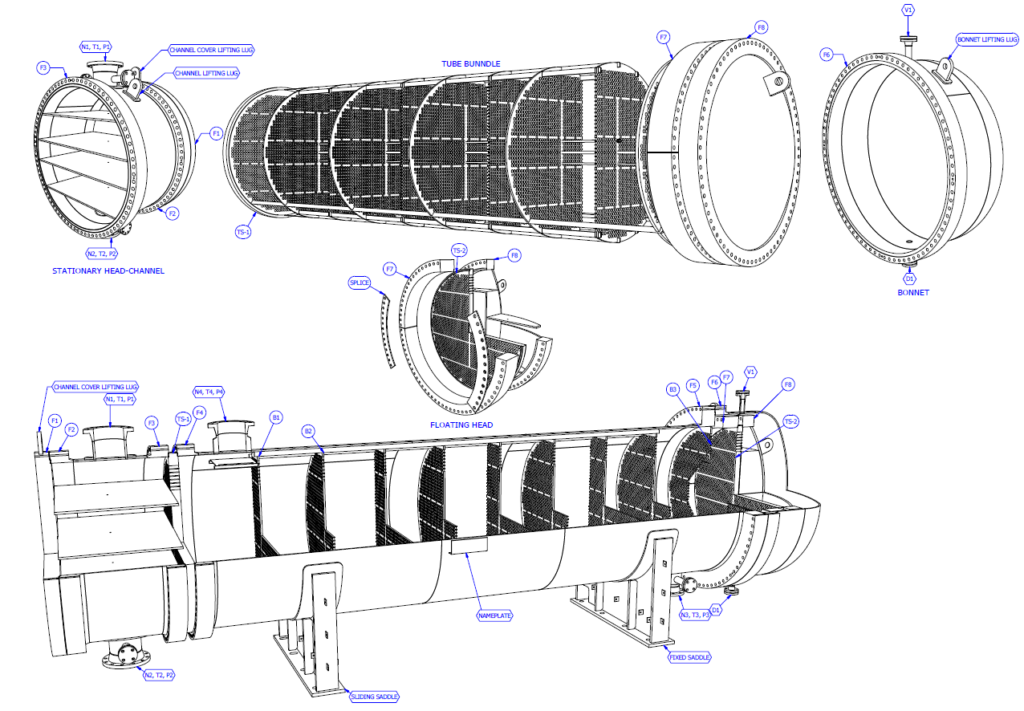

MECHANICAL DESIGN

Our engineers are experts in the design and mechanical optimization of heat transfer and under pressure equipment. We have a thorough understanding of all applicable codes and design references including ASME, TEMA and API 660 and are well versed in the interpretation of customer specifications.

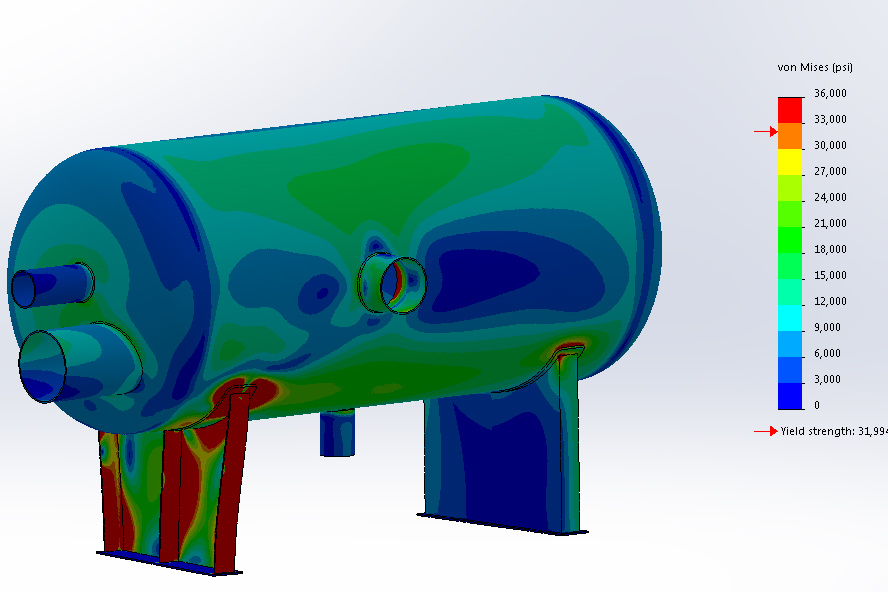

FINITE ELEMENT ANALYSIS

We use Finite Element Analysis softwares where code is not applicable geometry is complicated. Some applications of the FEA analysis would be designing complicated geometry such as expansion joint stress verification, tube-sheet design, calculations.

PROJECT ENGINEERING

When a project starts, we specify a team for technical management of the project, involving project lead engineer, procurement specialist, planning and project control specialist, fabrication engineer and project manager in order to manage the project technically and keep the project on track of plan.

DETAIL DRAWING

We have expert team of engineers with extensive knowledge of engineering for providing 2D Drawings and 3D Modeling. We prepare general assembly drawings for client review and approval as well as internal used fabrication detail drawings which is necessary for execution of the projects.

Computational Fluid Dynamics (CFD)

We use CFD which is a computational technology that uses numerical methods to solve and analyses the problems that involve fluid flows and thermal issues:

- Thermal Rating

- Agitation and Mixing

- Flow Dynamics

3D Modelling of Process Equimpent and Packages

3D Modelling

2D Fabrication Drawing

Fabrication Procedure

Material Selection

A variety of materials are used in the design of process equipment, including carbon steel, stainless steel, alloy steels, copper, bronze, brass, titanium and other various alloys. For example, regarding heat exchangers, the outer shell is made of a durable, high strength metal, such as graded carbon steel or stainless steel. Inner tubes require an effective combination of durability, corrosion resistance and thermal conductivity. All materials of construction is supplied according ASME BPVC, Sec II, and also specific requirements of client such as corrosion standards: SCC, HIC and NACE. For all cases we provide our client with the original or true copy of mill test certificates showing material specifications, chemical & mechanical properties and also any type of standard lab tests required by our client. These documents will be submitted at final stage of project and can be traced by client at any stage of fabrication according to inspection test plan of project.

- Carbon Steel

- Stainless Steel

- Non-ferrous alloy,

- Inconel, nickel, Hastelloy

- Titanium

Software Packages

Our engineering team is experienced and trained to use many different software packages and can exchange source files. Our design packages include:

- ASPEN and HTRI for thermal calculation

- Compress, PV Elite and DesignCalcs for ASME code calculations

- SolidWorks, CATIA and Inventor for modeling and drawing

- SolidWorks Simulation, ANSYS, Flow Simulation and Abaqus for advanced physics based problem solving

- Caesar II for pipe stress analysis

- We also have in-house developed spreadsheets for problems where commercial calculation packages cannot provide a solution