Home / Process Units

Process Units

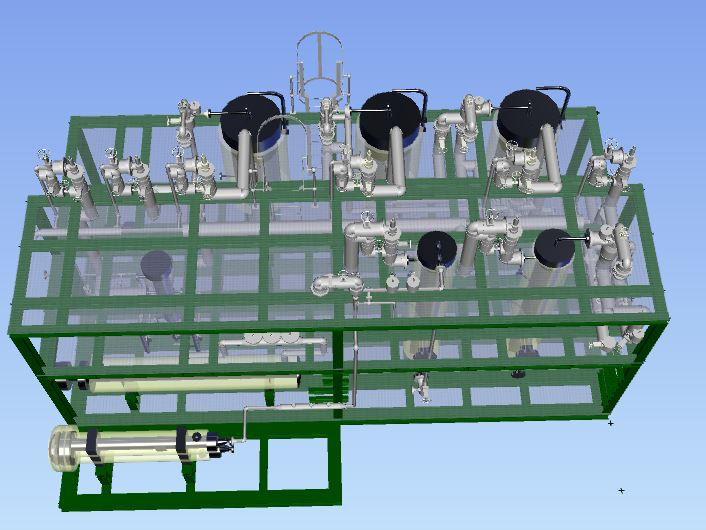

SKID MOUNTED UNIT

PROCESS UNIT

<div title=”Page 13″>Thanks to our own manufacturing facilities, we fabricate most of process equipment. Standard items such as rotary items, instruments , electrical any other necessary items will be procured according to project specifications. All components are rigorously tested prior to shipment, and the customer’s mechanical specifications, standards, and guidelines are precisely followed, assuring that the system will meet all the customer’s expectations. For each custom-built system, our engineers provide guidance throughout the entire project, including process development, engineering, installation assistance, training, and technical support.</div>

Engineering

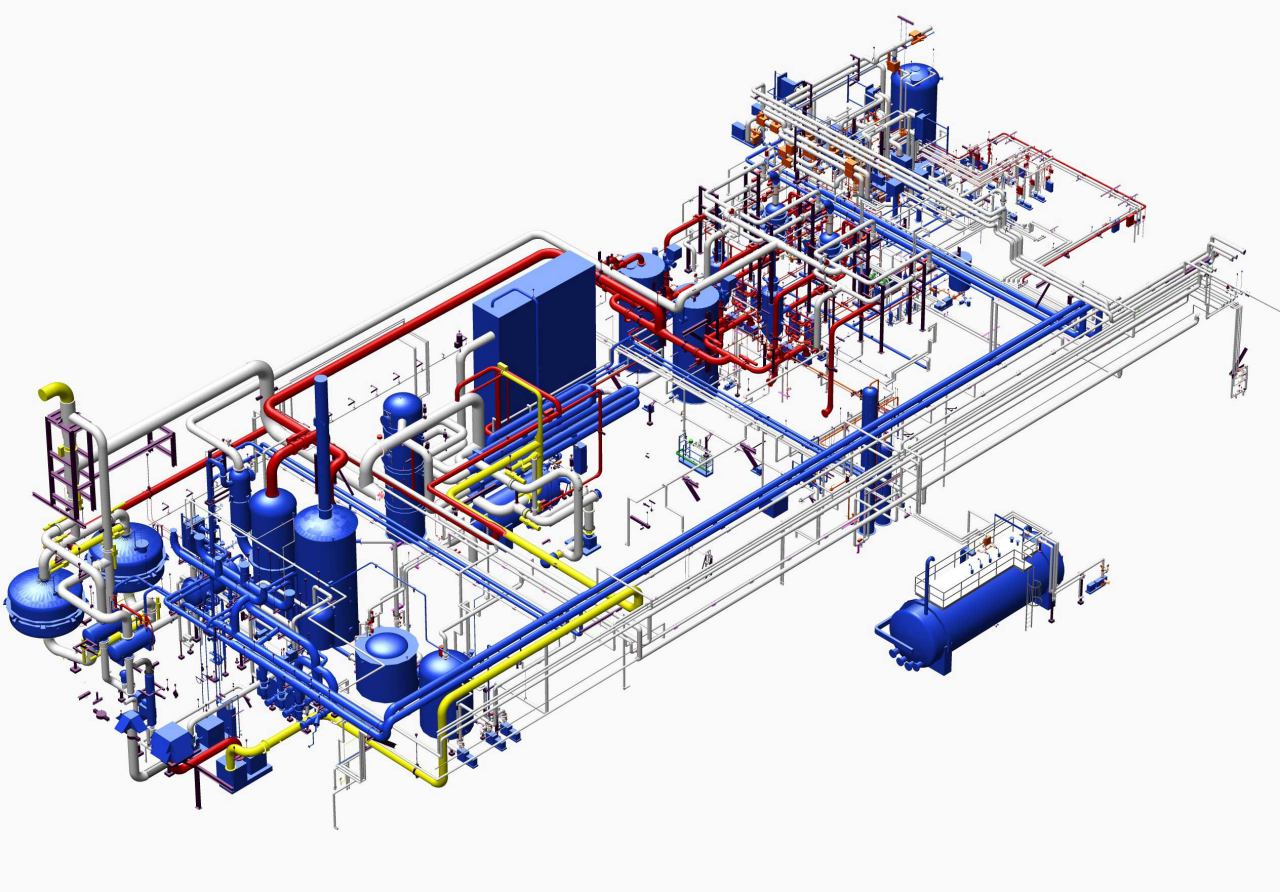

In the Detail Engineering phase, our engineers are responsible for generating the information package that establishes the specifications to execute the project´s construction, as well as the acquisition of Equipment, Instruments and Materials.

- PROCESS DESIGN

- EQUIPMENT ENGINEERING

- PIPING ENGINEERNG

- INSTRUMENTATION/ELECTRICAL

- CONTROL SYSTEM

PIPING ENGINEERING

- Construction specifications

- Implantation Equipment Plant

- Model 3D

- Piping Layouts

- Piping isometrics

- Piping supports

- Bill of Material

- Stress Analysis studies

- Steam Tracing Documents

EQUIPMENT DESIGN

- General Specifications

- Rotary Equipment Data Sheets/Calculation

- Fixed Equipment Calculation / Data Sheets

- Engineering Drawings

- 3D Model

PROCESS ENGINEERING

- Design basis

- Process flow diagram (PDF)

- Heat & mass balance

- Piping & instrument diagrams (P&IDs)

- Line list

- Equipment list

- Final line sizing

- Updated operating & control philosophy

- Commissioning procedure & plan

- Plant operating manual

Instrumentation / Electrical / Control

- Control and Operation

- Piping and Instrumentation Diagram

- Instrumentation Systems Specifications

- Block Diagram and / or Control Systems Architectures

- Instruments Data Sheets

- Instruments Location and

- Electrical routes

- Equipment Location and

- Control Cables Routes in Buildings

- Cables / Reel List

- Signal List

- Installation Details

- Loop Diagrams

- Electrical Load Analysis

- Electrical Equipment Data Sheets

- Grounding System

- PLC Programming