Home / Filters & Seperators

Filters & Separators

We supply standard and custom designed filtration packages, designed to maximize the performance of operation. Farnikan, in conjunction with well-known filter elements producers provides innovative solutions in the field of filtration, to a wide range of users in the processing and manufacturing industries. We employ our own capabilities in design and manufacture of some components of filtration packages such as Housing (Vessel) and also skid assemblies, customized piping assemblies, etc. All these packages, components and skids are designed, manufactured and tested in accordance with client’s specifications, and code requirements.

- Process Filters

- Self Cleaning Pulse Filter

- Strainers

- Purification Units

- Seperator Units

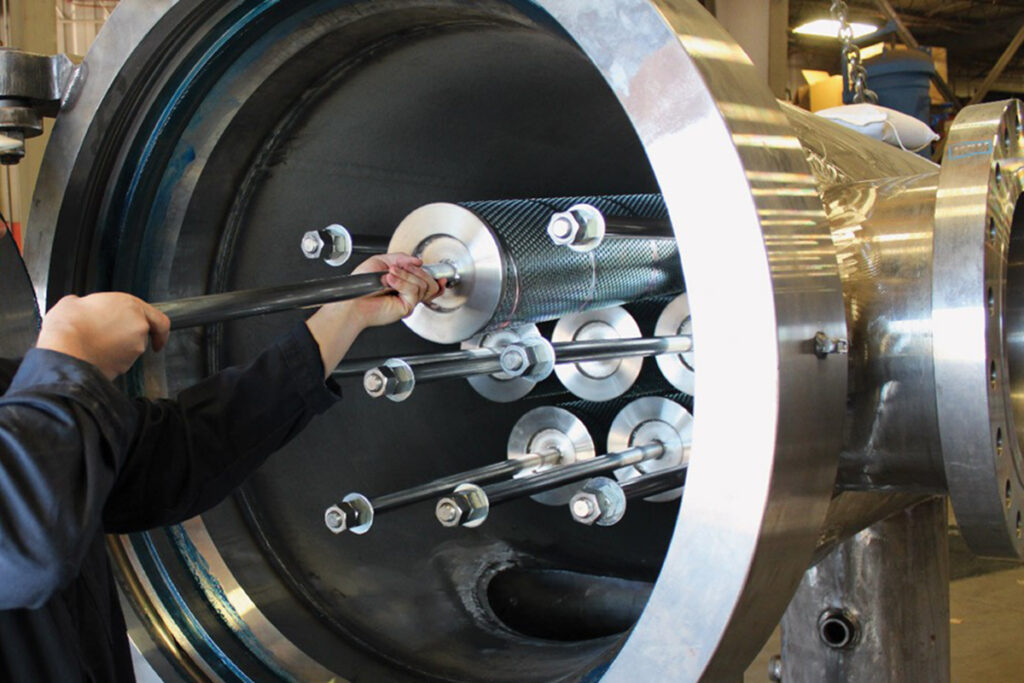

We specialize in the design and manufacture of high quality process filter vessels equipped with replacement filter elements and custom filter elements for a wide variety of industries. We also manufacture high pressure filter assemblies for demanding oil and gas and industrial and other similar industries and applications.

Filtration Solutions

PULSE CLEANING SYSTEM

FILTER VESSEL

SEPERATORS

STRAINERS

FILER CARTRIDGES

Filter Cartridge is considered the heart of filter; it is inserted inside the housing and used to remove the contaminant/particles from the fluid. The fluid enters from the inlet nozzle of housing and with the help of pressure, the fluid enters the cartridges which separates the contaminant/particles from the fluid.

Filter Elements / Internal Components

We supply our process filters with replacement filter elements and custom filter elements for a wide variety of applications. Our line of filter elements includes air, compressed air, compressed natural gas, oil, process media and transmission elements for numerous industrial and commercial applications. Filter cartridge which is encased within a housing or a casing is used to remove unwanted particles, pollutants, and chemicals from liquids. The cartridge is exposed to water, liquid or solvent that needs filtration, as it flows inside the housing and passes through the filter element.