Home / Skid Mounted Units

Skid Mounted Units

Thanks to our own manufacturing facilities, we fabricate most of process equipment. Standard items such as rotary items, instruments , electrical any other necessary items will be procured according to project specifications. All components are rigorously tested prior to shipment, and the customer’s mechanical specifications, standards, and guidelines are precisely followed, assuring that the system will meet all the customer’s expectations. For each custom-built system, our engineers provide guidance throughout the entire project, including process development, engineering, installation assistance, training, and technical support.

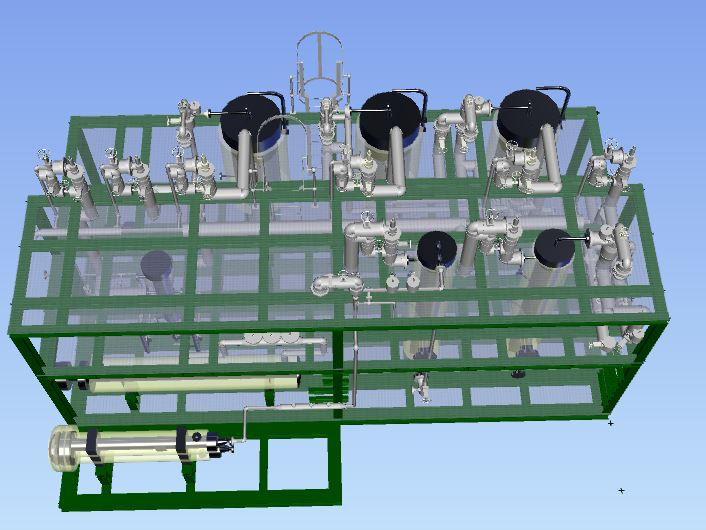

We have the capability to deliver Skid-Mounted Process Packages & Modular Systems to meet client’s specific requirements. These versatile skid-mounted systems are compact, easy to install, and require minimum field connections.

Each modular system is designed as a complete process unit and is prefabricated to the maximum extent possible so that the time and cost to the customer for field installation is minimized. The typical modular system will include columns, vessels, heat exchangers, pumps, and other types of process equipment, all mounted (where practical) within structural steel framing. This structural steel framing serves as a shipping support and is laid out to provide access to the equipment both during normal operation and for maintenance. To compliment these services, we are able to manufacture skid frames, install vessels, pumps, process equipment, valves, instrumentation, perform electrical installations, install insulation, fireproof and paint to international standards.

Advantages of Skid Mounted Units:

Skid mounted construction is one of the most efficient and cost effective methods of construction. The advantages can include:

- Lower construction costs

- Single point construction responsibility

- Reduced interruption to existing operations

- Reduced construction infrastructure at site

- Improved site safety

- Higher quality workmanship

- The best choice for construction in remote locations

- Skids can be moved to another location at a later date

- Skids can be fitted into sea containers for export

Engineering Know-How

- PROCESS DESIGN

- EQUIPMENT ENGINEERING

- PIPING ENGINEERNG

- INSTRUMENTATION/ELECTRICAL

- CONTROL SYSTEM

PROCESS PACKAGE

We are able to design and deliver custom designed process packages for specific process requirements. Packages that provide our clients with certified, flexible and cost effective equipment solutions. We can provide off-the-shelf solutions as well as exclusive designs for unique needs manufactured according to specific client requirements.

CHEMICAL INJECTION

Our custom designed Chemical Injection packages consist of multiple chemical services with associated single or several storage tanks or pressure vessels. The chemicals are transferred from the vessels to the injection point by means of chemical injection pumps, while flow rates can be adjusted locally or remotely in order to ensure that the correct amount of chemicals is injected.

OIL PURIFICATION

The Oil Purification System (OPS) is a filtration unit composing coalescing-separation dehydration system, vacuum dehydration system and impurities filtration system, able to maintain high oil quality by removing particles, water, corrosive gases and impurities enhancing oil lifetime, quality and safety. This system is specifically designed for oil purifying application of turbine and transformer.

METHANE PURIFICATION

We have know how and experience to deliver Methane Purification Unit by using Method of Catalyst Reforming. The system includes several reactors, Sulfur Removal Units, Heat Exchangers, Drums and other required process equipment. This system is used to purify Natural gas to purified methane with less than 0.05% of heavy hydrocarbons (C2+), Sulfur, CO, Co2 and other impurities.

PROCESS UNIT

We collaborate with international / local Licensor and basic engineering companies of process units for a specific solution, we design, fabricate and supply modules and components of these process units.

We are able to follow all the steps which is necessary for execution of complete small or medium sized projects based on Engineering, Procurement, and Construction (EPC) contract.