Home / Quality Control

Quality Control

Our Equipment are subjected to rigorous testing during the fabrication phase.They are visually examined by our inspectors and also by an authorized third party inspection company subjected to several tests according to Inspection Test Plan which is mutually agreed by us and our clients.

VISUAL TEST

VT method which is detection and evaluation of visual condition is used as classical NDT inspection focused on the detection of cracks, undercuts, and surface porosity, shape irregularities (e.g. linear misalignment, weld root concavity, casting die misalignment), and last, but not least general surface condition. The VT is full-value NDT method comparable with other (PT, MT, UT) and in its extent actually exceeds the scope of abilities of other methods. Visual testing represents one of the NDT methods that shall be performed before another NDT method is applied.

DYE PENETRANT TEST

Penetrant is deposited on the clean and dry surface of the part to be examined. Penetrant needs some “penetration” time to penetrate the surface opened imperfections. After this dwell time the excess penetrant shall be removed from surface and the developer is deposited on the surface. The developer is strong absorber, and withdraws the penetrant from discontinuities to the surface. After developing time it is possible to inspect presence of two-dimensional indications. Advantage is, that imperfections that are so small to be visible by human eyes, create larger indications. These indications create high contrast (color or brightness) on the background. Imperfection is detectable approximately from the width of microns.

ULTRASONIC TEST

Ultrasonic (UT) waves with a frequency of 500–5000 kHz are transmitted as a narrow beam toward a target. On reaching a metal surface with a flaw, the waves are reflected and returned to a suitable receiver. The time required for the return of the echo is a measure of the length of the path covered by the waves.

If used correctly, the ultrasonic method can approach the accuracy of radiography. The benefit of ultrasonic testing is that the equipment is portable; therefore, UT is useful when the weld is in an awkward location or needs to be examined on site.

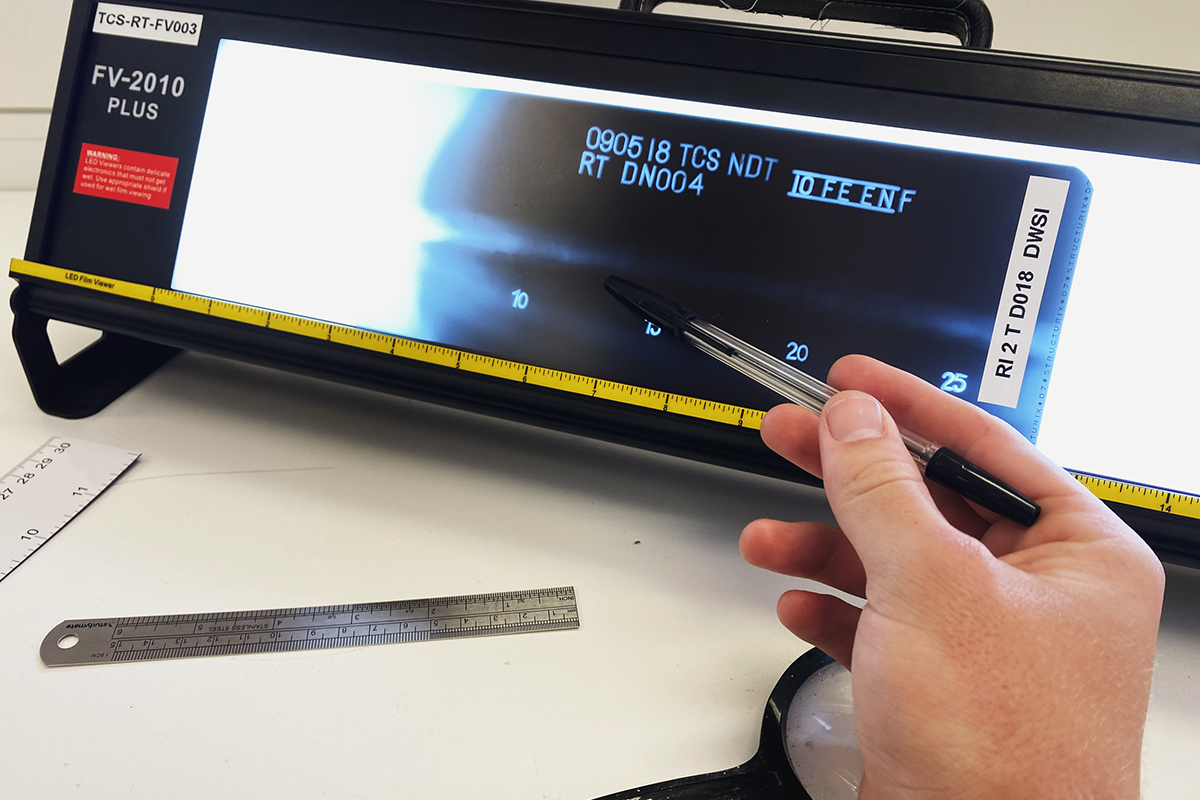

RADIOGRAPHIC TEST

Radiographic (RT) examination is the most useful nondestructive test, as it detects subsurface flaws invisible to the naked eye.

This method originally employed X-rays, but today pipe joints can be examined using gamma-rays produced by portable radioactive isotopes. All sources of radiation are potentially dangerous, and exposure over extended periods must be avoided. Personnel protection is often a requirement for technicians carrying out the radiography.

MAGNETIC PARTICLES TEST

Magnetic particle examination (MPE) is a non-destructive used to detect surface cracks on ferromagnetic materials, such as carbon steel.

Some low alloys are magnetic, however, austenitic-chromium stainless steel is very weakly magnetic and therefore excluded from this type of examination; this is subjected to dye penetrant examination, which is covered later. The MPE method is very useful for detecting fine cracks that are invisible to the naked eye.

PAUT TEST

Detection of discontinuities in high depth under surface . We use one of the new approaches, the PHASED ARRAY technique. This method is based on usage of a probe set, in combination with special electronic circuits, which could shape the beam. PHASED ARRAY probe consist of the set of miniature piezoelectric transducers. Setting of output parameters for each transducer separately forms the beam. This equipment has standard output signal in shape of the A-scan.

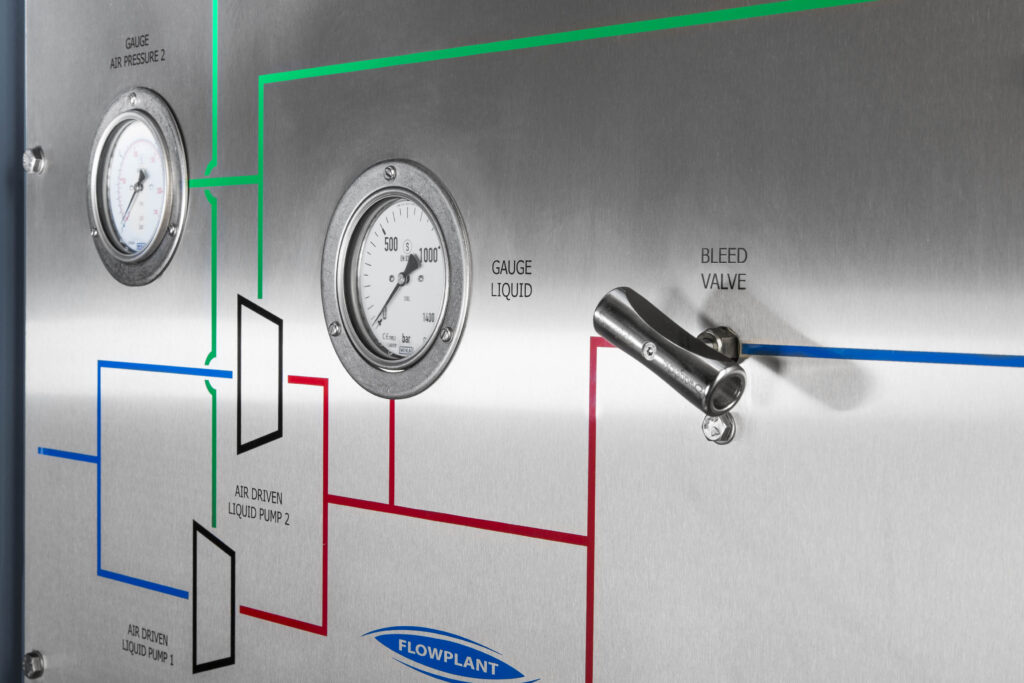

LEAK / HYDRO TEST

The purpose of the leak test and hydrostatic test is to simulate the real design stress on the vessel walls. So, this is the only way practically possible in a shop. We do air leak or soap test for checking tube to tube sheet joint in heat exchangers and also helium leak test if required by client. Each step will be inspected and under control of our qualified inspectors.

ACID WASHING / PAINTING

In stainless steel, the passivation process uses nitric acid or citric acid to remove free iron from the surface. The chemical treatment leads to a protective oxide layer, or passivation film, that is less likely to chemically react with air and cause corrosion. Passivated stainless steel resists rust. Painting is required for surface of equipment with carbon steel material after surface preparation. Each step will be inspected and under control of our qualified inspectors.

Inspection Test Plan

Our inspection and test plan will highlight many different testing and inspection tasks. For instance, destructive testing of materials may be done during the initial construction phase of the project to ensure that the materials have adequate properties and that the employees working with the materials have the required skill level for the project.

The inspection methods include ultrasonic testing, radiographic testing, visual inspection and any others. The timing and frequency of these inspections are determined in the inspection and test plan. The plan will also set up intervals of auditing to make sure that the necessary inspections have been performed and are sufficiently documented.

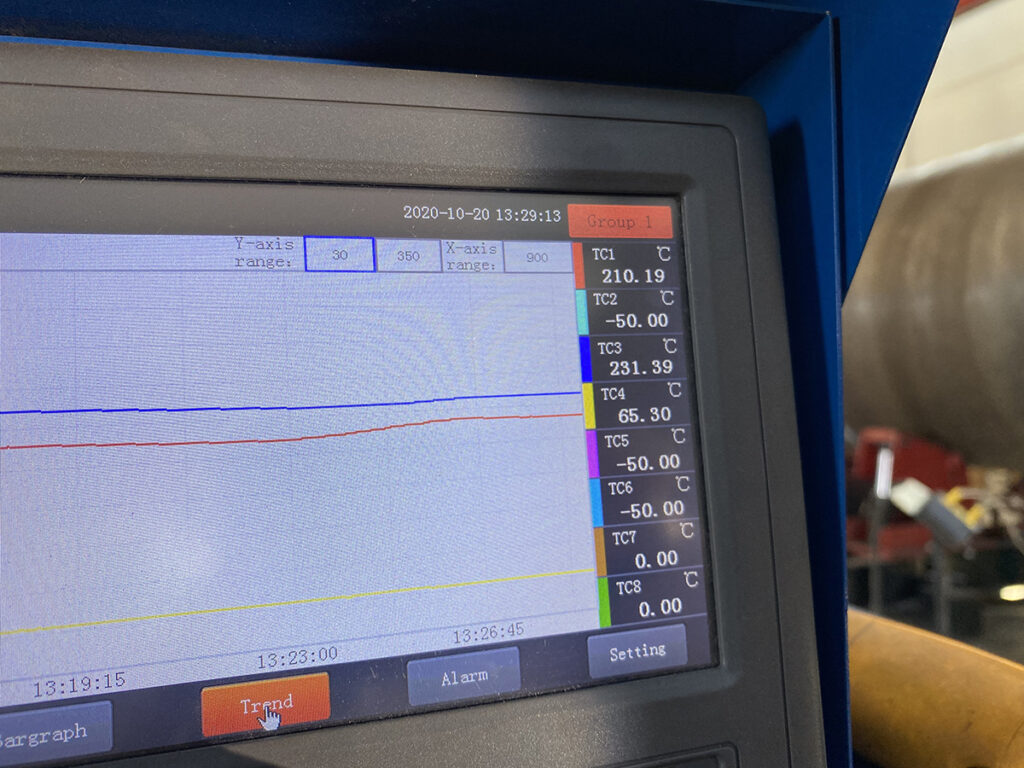

Heat Treatment

Pre-Heat: The process of preheating involves heating the area around the weld joint or the entire part to a specified temperature before welding. This reduces the cooling rate of the weld and drives out moisture, which in turn helps prevent hydrogen buildup and the potential for cracking. DHT and ISR is also sometimes necessary for alloy steel welding according to standards.

PWHT: Post-weld heat treatment (PWHT) is applied to steel assemblies primarily to reduce the likelihood of brittle fracture by reducing the level of tensile welding residual stresses and by tempering hard, potentially brittle, microstructural regions.

Our inspectors check all the steps according to procedures and witness the process and provide confirmed graphs as records.

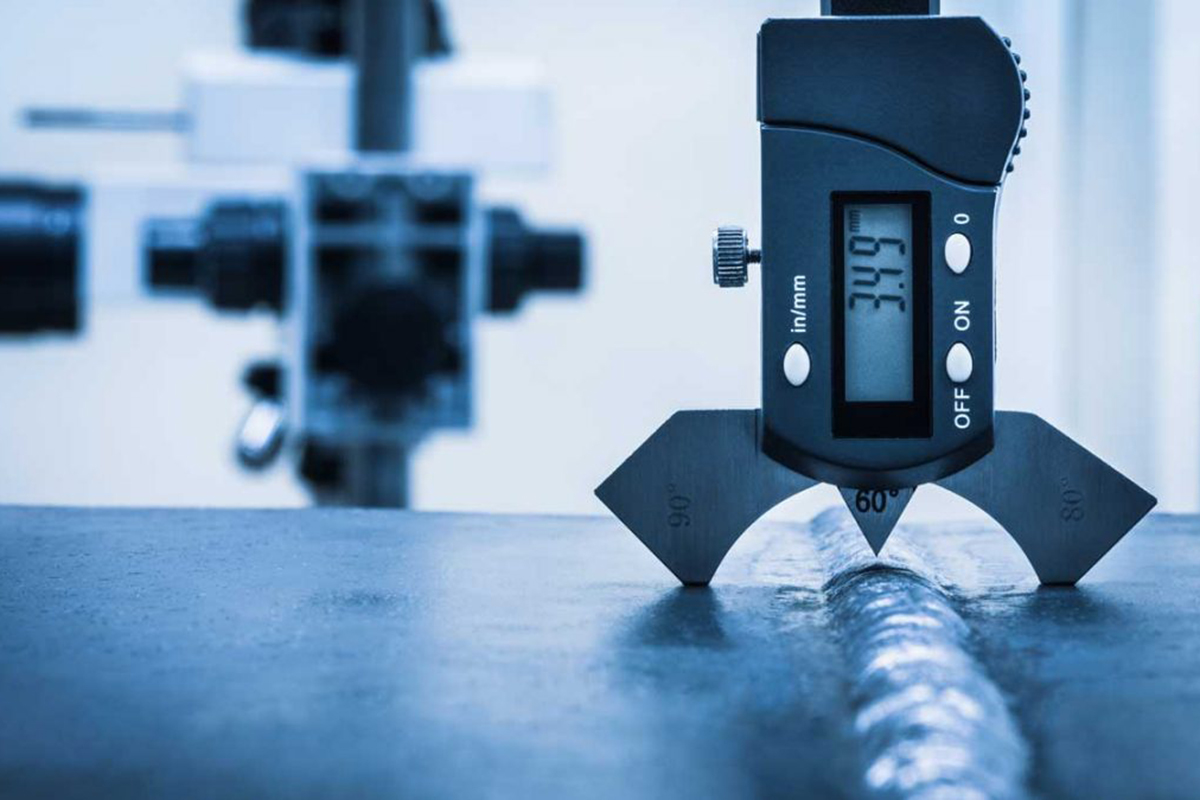

Welding Inspection

Our inspectors check all the steps according to welding procedures (WPS) based on welding maps. They check the procedures and witness the process and provide the relevant reports.

- Submerged Arc Welding (SAW)

- Flux-core Welding (FCAW)

- Manual Welding

- MIG Welding (GMAW)

- TIG Welding (GTAW)

- Stick Electrode Welding (SMAW)

Quality Concerns

Our fabrication services are the preferred choice for those clients who seek for modern, accurate, agile and precise manufacturing of equipment serving the Oil & Gas, Refineries, Petrochemicals and Power Sectors.

Our commitment to the clients is proven by the quality management system & Occupation Health & Safety Management System certifications.

QC Dossier

We will provide all the clients with QC dossier according mutual agreed procedure whether in electronic files or printed booklets:

- Material Identification

- Welding Documents (WPS/PQR)

- MTC of Materials

- Dimensional Reports

- NDT Reports

- As-Built engineering technical documents

- Technical Procedures

- Inspection records