Home / Pressure Vessels

Pressure Vessels

We are experienced in custom designing pressure vessels to ASME code standards. We take great care in understanding our customer’s requirements to insure the most optimum design providing a cost effective and safe pressure vessel. All vessel designs are done to ASME standards to produce vessels that meet the internal pressures, operating temperature, wind and seismic loading, corrosion allowance and volume specified. Documentation is provided per customer specifications from a simple package including engineering drawings and ASME calculations to a full documentation package with as-built drawings, calculations, MTR`s, test procedures and reports

We have the experience and engineering expertise:

- Pressure Vessels

- Tower and Columns

- Process Reactors

- Storage Vessels

We design and fabricate the ASME pressure vessels and tanks with custom configurations to meet client’s specific application requirements. Our knowledge combined with the utilization of advanced engineering tools and fabrication standards enable us to meet the stringent regulations set by ASME. Our fabrication facility is well-equipped with various latest welding equipment. As a result, we conduct a variety of welding procedures to fabricate a pressure vessel.

Types of Pressure Vessels

Process vessels are components in which various processes are performed. Such as breaking down a product, combining product, removing various elements or aspects of a product and more. Process vessels are usually specialized designs for their specific process and require unique construction materials or multiple material types.

PROCESS PRESSURE VESSELS

We design, construct and fabricate various kind of ASME code pressure vessels, steam drums, storage tanks and components. Our fabrication process is highly reliable and produces consistent quality; backed up by our well-developed quality control program.

COLUMNS & TOWERS

We are able to design and fabricate distillation towers, columns which are essential items used in the distillation of liquid mixtures to separate the mixture into its component parts, or fractions, based on the differences in volatilities. These equipment are mostly used in refineries. We also provide towers for petrochemical plants.

PROCESS REACTORS

Process reactor pressure vessels are the hearts of the processing units in refineries and petrochemical plants. Specific process reaction will be accrued in the vessels by means of chemicals and flow. We design, construct and fabricate ASME code reactors as well as internal distributor for specific process requirement.

ASME Rules

Our expert pressure vessel fabrication department follows the ASME organization’s guideline which increases the service life of the made-to-order pressure vessels and equipment we produce. We follow the ASME in order to follow important safety design rules along with rules related to the construction, operation, testing and maintenance of pressure vessels, boilers, heat exchangers and other pressure systems.

We have invested in the most advanced welding equipment and welding techniques known in the industry. We comply with the highest welding-standards to ensure the quality of our equipment.

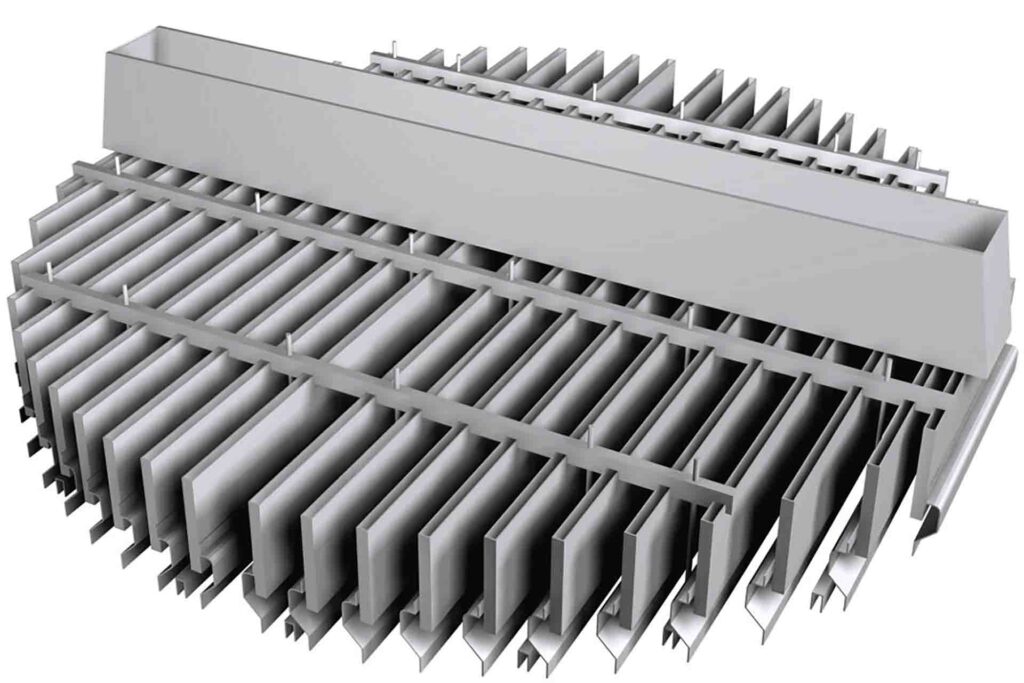

Internal / External Components

Farnikan also supplies all types of vessel internal components, including:

Coalescers, Trays, Vane and Mesh Mist Extractors, Distributors, Baffles, Support Beds, U-tube & Heating & Cooling Coils designed to type and material spec.

Ladders and Platforms and other external components that shall be attached to main body of vessels are also available to supply according to standard specs of clients.

Types of Pressure Vessels

- Drums

- Tower and Columns

- Process Reactors

- Storage Vessels